Product Description

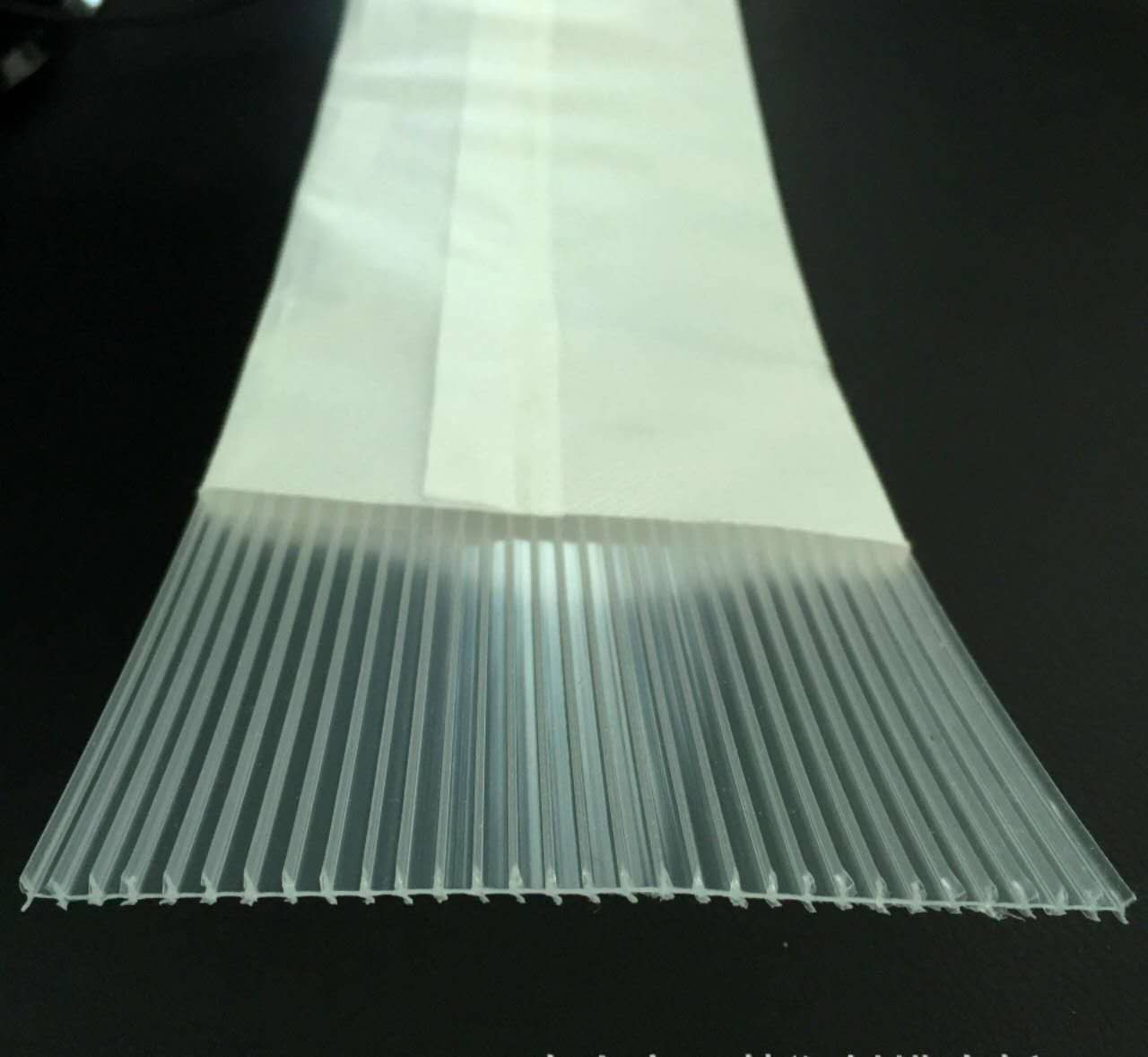

PE Laminated GCLs consist of a layer of bentonite encapsulated between two geotextiles (nonwoven and woven polypropylene geotextiles), needle punched together and laminated on one side to a polyethylene membrane for maximum performances under a wide variety of field conditions. This integrated matrix of bentonite and needle punched fibers provides high shear strength and allows the PE Laminated GCLs to keep low permeability even in presence of adverse installation conditions. The PE Laminated GCLs have high internal shear strength characteristics for steep slope applications.

Application:

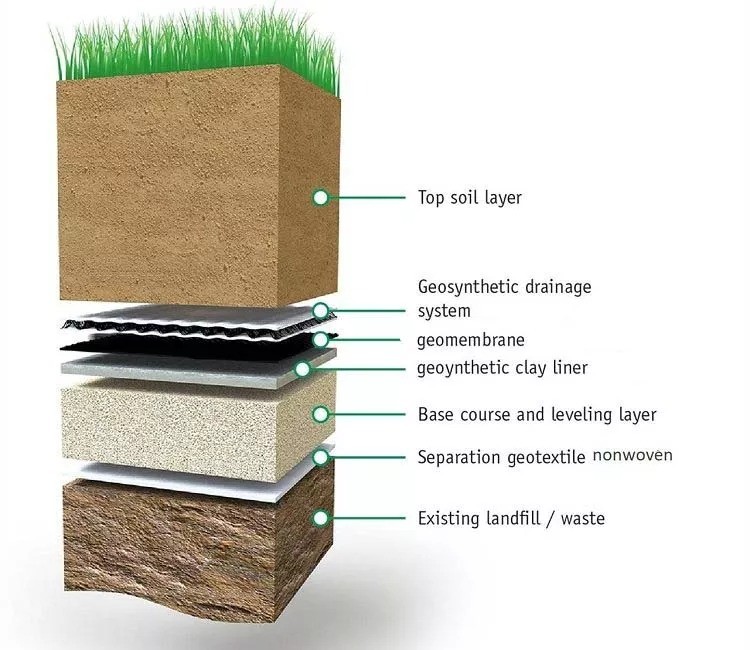

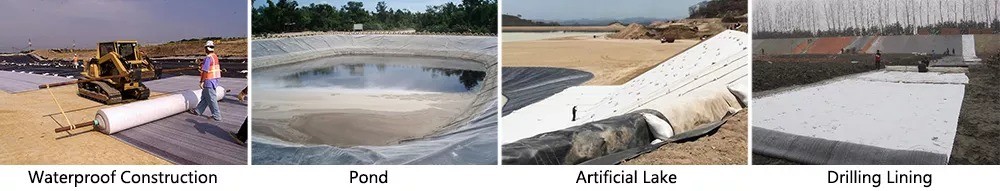

- Landfill caps, closures, and base seal

- Environmental protection under roads, railways, airports

- Dams and dikes

- Water containment and pond applications

- Structural waterproofing

- Secondary containment

- Mining applications

- Tunnels

Specification

| Inspection Item | Testing Procedure | Technical Index |

| Bentonite mass for unit area | ASTMD5993 | ≥5.5kg/m2 |

| Expansion coefficient | ASTMD5890 | ≥ 26mL/2g |

| Low-temperature ductility | ASTMD5898 | No impact at -35°C |

| Thickness | ASTMD5892 | ≥6.4mm |

| Tensile strength | ASTMD4632 | ≥540N |

| Peel strength of the concrete face | ASTMD4632 | ≥3.0 KN/ m2 |

| Peel strength | ASTMD4632 | ≥68N |

| Indicated flow | ASTMD5887 | ≤1 × 10-8m3/m2/sec |

| Hydrostatic pressure resistance | ASTMD5888 | ≥70 |

| Permeability | ASTMD5887 | ≤5 × 10-12cm/sec |

| Extension rate | ASTMD5896 | ≥20 |

| Puncture strength | ASTMD5894 | ≥635N |